Which sensors are used in oil and gas industry?

Introduction

The oil and gas industry utilizes various sensors, including pressure sensors for pipeline monitoring, temperature sensors for equipment safety, flow sensors for leak detection, and level sensors for tank management. Gas sensors detect hazardous gases, while vibration sensors enable predictive maintenance. Corrosion sensors monitor pipeline integrity, and acoustic sensors identify leaks. Position sensors automate valve control, and humidity sensors prevent hydrate formation. Optical sensors analyze gas composition, and wireless sensors support remote monitoring. Multiphase flow sensors optimize production, and seismic sensors aid exploration. Smart sensors integrate IoT for real-time data analysis and process optimization.

Everything about types of sensors used in oil and gas industry

Pressure Sensors

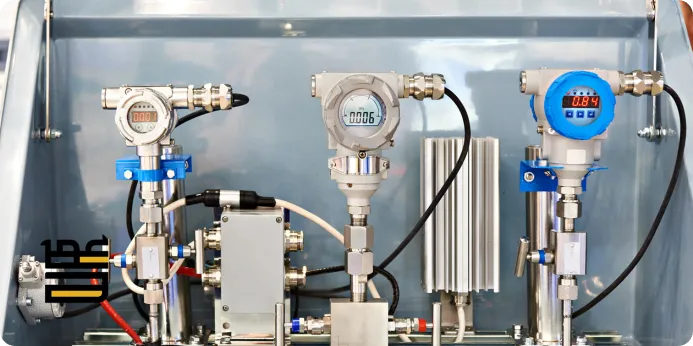

Pressure sensors are critical in the oil and gas industry for monitoring and controlling pressure levels in pipelines, tanks, and equipment. They ensure operational safety, optimize production, and prevent equipment failures. These sensors are among the essential “types of sensors used in the oil and gas industry” playing a key role in maintaining efficiency and safety. Companies like Abb in dubai are key providers of these technologies, offering a wide range of solutions for the sector.

What are pressure sensors used for in the oil and gas industry?

Pressure sensors measure pressure in pipelines, wellheads, and storage tanks to ensure safe and efficient operations. They are also used in safety systems to detect overpressure or underpressure conditions.How do pressure sensors improve pipeline safety?

By continuously monitoring pressure, these sensors detect leaks, blockages, or abnormal pressure changes, preventing accidents and ensuring pipeline integrity.What are the key features of high-performance pressure sensors?

High-performance pressure sensors are durable, resistant to harsh environments, and provide high accuracy. They often feature corrosion-resistant materials, wide temperature ranges, and compatibility with remote monitoring systems.

These features make pressure sensors essential for maintaining safety and efficiency in the oil and gas industry. with companies like Siemens in Dubai playing a key role in their provision.

Temperature Sensors

Temperature sensors are essential in oil and gas operations for monitoring and controlling temperature to ensure safety, efficiency, and equipment longevity. These sensors are among the key types of sensors used in the oil and gas industry, playing a vital role in maintaining operational standards.

Why are temperature sensors critical in oil and gas operations?

They monitor process temperatures in pipelines, reactors, and storage tanks, ensuring optimal conditions and preventing damage to equipment and materials.How do temperature sensors prevent equipment overheating?

By providing real-time temperature data, these sensors trigger alarms or shutdown systems when temperatures exceed safe limits, preventing overheating and potential failures.What temperature ranges can industrial temperature sensors handle?

Industrial temperature sensors can operate in a wide range, typically from -200°C to over 1000°C, depending on the type and application, ensuring reliability in extreme conditions.

These capabilities make temperature sensors vital for maintaining operational efficiency in the oil and gas industry. particularly in regions where companies like Yanmar in UAE offer strong local support and expertise.

Flow Sensors

Flow sensors are vital in the oil and gas industry for measuring and optimizing the flow of liquids and gases, ensuring efficient production and pipeline safety. These sensors are among the key types of sensors used in the oil and gas industry, playing a crucial role in maintaining operational efficiency and safety.

How do flow sensors optimize oil and gas production?

Flow sensors provide real-time data on flow rates, enabling operators to adjust processes, reduce waste, and maximize production efficiency.

What types of flow sensors are used for gas and liquid measurement?

Common types include turbine flow sensors, ultrasonic flow sensors, and Coriolis flow sensors, each suited for specific applications like gas pipelines or liquid measurement.

How do flow sensors detect leaks in pipelines?

By monitoring flow rates, these sensors identify discrepancies between expected and actual flow, triggering alarms for potential leaks or blockages.

These features make flow sensors essential for maintaining operational efficiency and safety in the oil and gas industr

Level Sensors

Level sensors are critical in the oil and gas industry for measuring the level of liquids or solids in tanks and vessels, ensuring efficient storage and inventory management.

Definition: Level sensors measure the level of liquids or solids in tanks and vessels, providing accurate data for process control.

Applications: They are used for monitoring oil and gas storage levels, preventing overflows, and managing inventory in storage facilities.

Key Features: These sensors feature a non-invasive design, high accuracy, and resistance to harsh chemicals, making them reliable in demanding environments.

These capabilities make level sensors essential for maintaining operational efficiency and safety in the oil and gas industry. with companies like Siemens in Iraq offering advanced solutions in this area.

Gas Sensors

Gas sensors are essential in the oil and gas industry for detecting hazardous gases, ensuring safety, and preventing accidents.

| Aspect | Details |

| Enhancing Safety | Gas sensors detect leaks of hazardous gases, triggering alarms and preventing explosions or health risks. |

| Commonly Detected Gases | Methane (CH₄), hydrogen sulfide (H₂S), carbon monoxide (CO), and volatile organic compounds (VOCs). |

| Explosion-Proof Design | Gas sensors are built with rugged, sealed enclosures and materials that prevent ignition in explosive environments. |

These features make gas sensors vital for maintaining safety and compliance in the oil and gas industry.