How accurate is the Endress Hauser magnetic flow meter?

Introduction

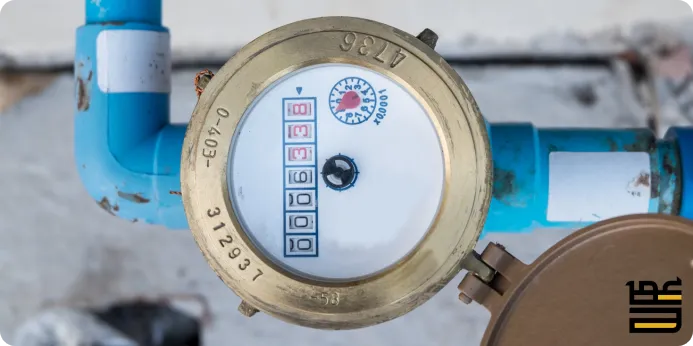

Endress+Hauser magnetic flow meters are widely utilized in the oil, gas, and petrochemical sectors for their ability to provide accurate and reliable flow measurements in challenging environments. These meters operate on Faraday’s Law of Electromagnetic Induction, ensuring precise measurement of conductive liquids, even in the presence of harsh conditions such as high temperatures, pressures, and corrosive or abrasive fluids.

Their obstruction-free design eliminates pressure drops and reduces maintenance requirements, making them ideal for diverse applications ranging from crude oil extraction and refining to custody transfer and process control. Endress+Hauser offers a broad range of magnetic flow meters tailored to the specific needs of the oil, gas, and petrochemical industries, ensuring optimal performance and operational efficiency.

Everything about Endress Hauser magnetic flow meter

Advantages of Endress Hauser Magnetic Flow Meters

Endress Hauser magnetic flow meters, also known as electromagnetic flow meters, offer a number of distinct advantages that make them a popular choice for a variety of industrial flow measurement applications.

- Wide Range of Applications: They can be used to measure the flow of virtually any conductive liquid, including water, acids, alkalis, slurries, and more. This versatility makes them suitable for a wide range of industries, from water and wastewater treatment to chemical processing and food & beverage.

- High Accuracy and Reliability: Endress Hauser Magmeters provide highly accurate and reliable flow measurements, typically within ±0.5% of the actual flow rate. This accuracy is largely unaffected by changes in fluid properties such as pressure, density, temperature, and viscosity.

- No Obstruction to Flow: Unlike mechanical flow meters, magnetic flow meters have no moving parts or obstructions in the flow path. This eliminates pressure loss, reduces maintenance requirements, and makes them suitable for measuring the flow of liquids with suspended solids or abrasive particles.

- Low Maintenance: With no moving parts to wear out, magnetic flow meters require minimal maintenance. This can translate into significant cost savings over the lifetime of the instrument.

- Hygienic Design: Many Endress Hauser magnetic flow meters are designed with hygienic applications in mind. They feature smooth, crevice-free surfaces and are often CIP (Clean-in-Place) and SIP (Sterilize-in-Place) compatible, making them ideal for use in the food & beverage and pharmaceutical industries.

- Energy Efficient: The absence of flow obstruction means no additional energy is required to overcome pressure loss, contributing to energy savings.

What are Applications of Endress Hauser Magnetic Flow Meters?

Endress Hauser magnetic flow meters, also known as magmeters, have a wide array of applications across various industries due to their versatility and reliability. They primarily measure the flow rate of conductive liquids, making them suitable for numerous processes and applications.

- Water and Wastewater Management: Endress Hauser Magmeters are extensively used in water treatment plants, wastewater treatment facilities, and irrigation systems to monitor and control water flow. They can handle a variety of liquids, including raw water, treated water, wastewater, and sludge.

- Process Industries: In the chemical, pharmaceutical, and petrochemical industries, magmeters measure the flow of various chemicals, acids, alkalis, and solvents. They offer precise measurements even in harsh conditions, making them ideal for demanding process environments.

- Food & Beverage Industry: Endress Hauser Magmeters ensure hygienic and accurate flow measurement of various liquids like juices, milk, beer, and other beverages. Their non-intrusive design and CIP (Clean-in-Place) capability are particularly valuable in maintaining food safety standards.

- Life Sciences: In pharmaceutical and biotechnological applications, magmeters measure the flow of various liquids like cell cultures, buffers, and reagents. Their accuracy and sterility are critical in ensuring the quality and consistency of these processes.

- Power Generation: Magmeters are employed in power plants to measure the flow of feedwater, cooling water, and other process liquids. Their robust construction and high accuracy contribute to efficient power generation.

Through collaborations with local entities, Siemens in Saudi Arabia is helping to drive sustainability and innovation across various sectors. Additionally, Siemens has established training programs in the country to enhance the skills of the local workforce, particularly in technical fields.

How to Choose the Right Endress Hauser Magnetic Flow Meter?

“Endress Hauser magnetic flow meter” offers a wide range of magnetic flow meters, each designed for specific applications and environments. To select the most suitable meter for your needs, consider these factors:

Fluid Properties

- Conductivity: Magnetic flow meters require a minimum fluid conductivity to operate effectively. Check the minimum conductivity requirements of the meter and compare it to your fluid’s conductivity.

- Viscosity: High viscosity fluids can impact the accuracy of magnetic flow meters. Consider meters designed for high-viscosity applications if necessary.

- Temperature: Ensure the meter’s liner and electrode materials are compatible with your fluid’s operating temperature range.

- Chemical Compatibility: The meter’s wetted parts must be resistant to the chemicals present in the fluid to prevent corrosion and ensure accurate measurements.

Application Requirements

- Flow Rate Range: Determine the minimum and maximum flow rates in your application and select a meter with a suitable measuring range.

- Accuracy: Choose a meter with the required accuracy level for your application. Custody transfer applications often demand higher accuracy than general process monitoring.

- Process Conditions: Consider factors like pressure, temperature fluctuations, vibration, and potential for electromagnetic interference when selecting a meter.

- Installation: Evaluate the available space for installation and choose a meter with appropriate dimensions and connection options.

Installation of Endress Hauser magnetic flow meter

Before diving into the physical installation, it’s essential to prepare adequately. This involves selecting the right flow meter size and lining material based on the specific application and fluid characteristics. Ensure you have all the necessary tools and equipment on hand, along with reviewing the Endress Hauser magnetic flow meter installation manuals specific to your model.

The mechanical installation of flow meters involves mounting the flow meter into the pipeline. It’s critical to ensure proper alignment and orientation of the flow meter, as well as considering factors like upstream and downstream straight pipe requirements. The use of appropriate gaskets and seals is vital to prevent leaks and ensure accurate measurements.

Once the flow meter is securely in place, the next step is to connect the electrical wiring according to the manufacturer’s instructions. This typically involves power supply connections, signal output connections, and possibly grounding. After the connections are made, the flow meter needs to be configured using its local display or communication interface. This includes setting parameters such as flow units, measurement range, and output scaling.

With the installation and configuration complete, the final stage is commissioning and verification. This involves checking for proper operation, zeroing the flow meter if necessary, and verifying the accuracy of the measurements. It’s advisable to compare the flow meter readings against other flow measurement devices or known flow rates to ensure reliable performance.

Endress+Hauser offers a comprehensive range of magnetic flow meters tailored to various industrial needs. Their products stand out for their accuracy, reliability, and adaptability to diverse applications, from hygienic processes in the food industry to demanding conditions like high temperatures or custody transfer situations.

Endress+Hauser prioritizes ease of use throughout the product lifecycle, simplifying everything from engineering to maintenance. Their commitment to innovation is evident in features like Heartbeat Technology, which ensures measurement reliability and enables longer calibration intervals. Whether it’s a basic water application or a complex industrial process, Endress+Hauser has a magnetic flow meter solution designed to meet specific requirements, backed by their reputation for quality and performance.