types of compressor in oil and gas industry

Introduction

In the oil and gas industry, several types of compressors are employed. Centrifugal compressors are frequently used for high-volume, continuous-flow applications, such as gas transmission pipelines. Reciprocating compressors, characterized by their piston-driven operation, are well-suited for intermittent high-pressure services, including gas injection. Screw compressors, known for their rotary motion, efficiently handle processes such as vapor recovery and gas gathering. Axial compressors are applied when large volume flow is needed. Diaphragm compressors are used in applications where process gas purity is very important.

Everything about types of compressor in oil and gas industry

types of compressor in oil and gas industry, Reciprocating Compressors

Reciprocating compressors are a significant subset of the “types of compressor in oil and gas industry”. Understanding Types Of Industrial Gas Compressors, including reciprocating types, is crucial to grasp their diverse applications:

- Gas Lift: They pressurize gas injected into oil wells to enhance oil recovery by reducing the fluid’s density.

- Gas Gathering: These compressors play a crucial role in collecting gas from multiple wells and boosting it to a higher pressure for processing or pipeline transport. This is a vital application of reciprocating compressors in oil and gas operations.

- Pipeline Compression: While often centrifugal compressors are used, reciprocating units can be employed in pipelines, especially for lower flow rates or intermittent service to maintain pressure.

- Fuel Gas Boosting: They increase the pressure of natural gas used as fuel in gas turbines or engines on-site.

- Gas Reinjection: Used to increase reservoir pressure by injecting gas back into the formation.

- CNG (Compressed Natural Gas): Reciprocating compressors are used to fill CNG tanks.

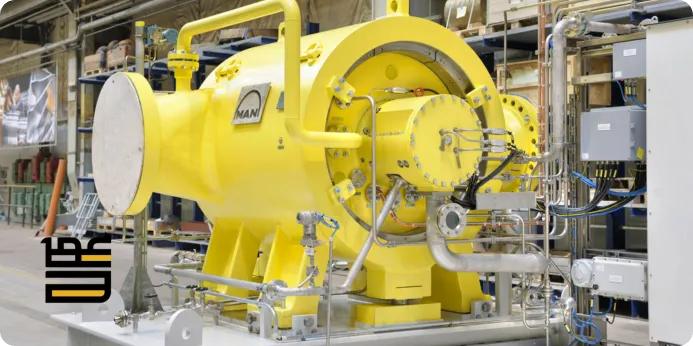

Centrifugal Compressors A Core Technology in Gas Processing

Centrifugal Compressors are a vital component among the various types of compressor in oil and gas industry, particularly within gas processing facilities. Their design and operational characteristics make them ideal for specific tasks:

- High-Volume Gas Handling: They excel at continuously moving substantial volumes of gas, making them indispensable in large-scale processing plants.

- Pipeline Compression: These compressors maintain the pressure required for efficient gas transport through extensive pipeline networks.

- Gas Reinjection: In some cases, they are used for reinjecting processed gas back into reservoirs to enhance oil recovery or for storage purposes. Companies like Flowserve in Oman provide specialized equipment and services for various oil and gas applications, including gas reinjection.

- Refrigeration Processes: Centrifugal compressors are key components in refrigeration systems used for gas liquefaction and processing.

- Gas Turbine Compressor: They provide compressed air to the combustion chamber.

Their ability to handle large volumes at varying pressures solidifies their position as a cornerstone technology in gas processing operations. {For instance, major companies like ABB in Dubai utilize these compressors extensively in their gas processing plants due to their reliability and efficiency.

Rotary Screw Compressors: Mechanism and Advantages

Rotary Screw Compressors represent a significant category within the types of compressor in oil and gas industry. Their unique mechanism and operational benefits contribute to their widespread use.

Mechanism

These compressors utilize two intermeshing helical screws, known as rotors, within a tightly fitted casing. As the rotors turn, gas is drawn in, trapped between the screws, and progressively compressed as the volume of the space containing the gas decreases along the length of the rotors. Companies like Honeywell in Saudi Arabia often employ these compressors in their oil and gas operations due to their efficiency and reliability.

Continuous Flow

Rotary Screw Compressors provide a constant, pulse-free flow of compressed gas, making them suitable for applications requiring a steady supply.

Oil-Flooded and Oil-Free Variants

Oil-flooded versions use oil for lubrication, cooling, and sealing, offering high efficiency, while oil-free models are employed when process gas purity is paramount.

Compact Design

Their relatively compact design compared to some other compressor types allows for easier installation in space-constrained environments.

Low Maintenance

Fewer moving parts, compared to reciprocating compressors, often translate into reduced maintenance requirements and enhanced reliability. They are also used for low-flow applications. For example, the implementation of such advanced compressor systems is crucial for companies like Siemens in Iraq, where reliable and efficient gas compression is essential for various industrial applications

Axial Compressors in Gas Turbine Operations

Axial Compressors are one of the compressor used in the oil and gas industry, primarily within gas turbine operations. They are essential for providing a continuous flow of compressed air to the combustion chamber. The design features multiple stages of rotating blades (rotors) and stationary vanes (stators) that progressively increase the air pressure. They are known for their high efficiency at design conditions and are particularly well-suited for high-volume, relatively low-pressure ratio applications.

Companies like Endress Hauser in Dubai often provide instrumentation and automation solutions that integrate with such compressor systems, ensuring their optimal performance and monitoring.

Here’s a table summarizing key aspects of their role in gas turbines:

| Feature | Description |

| Primary Function | Supplies compressed air for combustion. |

| Airflow | High-volume, continuous, axial flow. |

| Pressure Ratio | Lower per stage, high overall with multiple stages. |

| Efficiency | Highly efficient at design point. |

| Operational Range | Narrow operational range. |

| Maintenance | Regular inspections needed. |

| Key Advantage | Delivers large air mass flow for efficient combustion. |

| Typical Applications | Power generation, aircraft engines, industrial gas turbines. |