How to Choose theTemperature Transmitter for our industry?

Introduction

Temperature is a critical factor in countless industrial processes, from manufacturing to food production to energy generation. Maintaining precise temperature control is essential for product quality, safety, and efficiency. That’s where temperature transmitters come in. Temperature transmitter technology is constantly evolving. We can expect to see even more accurate, reliable, and intelligent transmitters in the future.

Everything about temperature transmitters

What is a Temperature Transmitter?

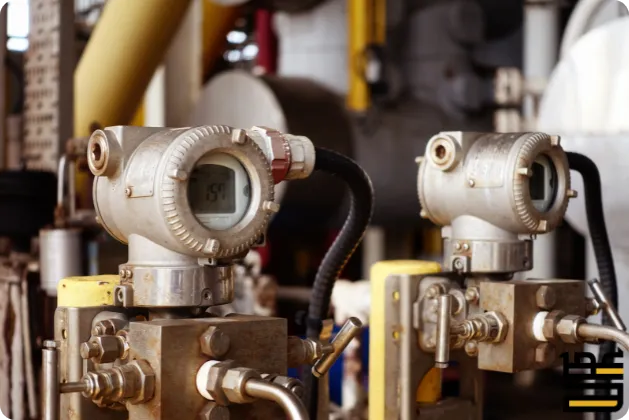

Temperature transmitters are electronic devices that interface with a temperature sensor (such as a thermocouple, RTD, or thermistor). It takes the electrical signal generated by the sensor, which is often small and susceptible to interference, and converts it into a standardized, more robust signal that can be easily transmitted and understood by control systems, monitoring equipment, or data loggers.

Key functions of a temperature transmitter:

- Signal Conversion: Translates the sensor’s raw signal into a standard format, usually 4-20 mA current loop or 0-10V DC voltage.

- Signal Amplification: Boosts the weak signal from the sensor to a level suitable for transmission over long distances.

- Signal Isolation: Electrically separates the sensor from the rest of the system, protecting it from ground loops and other electrical noise.

- Linearization: Corrects for any non-linearity in the sensor’s output, ensuring a proportional relationship between the measured temperature and the output signal.

- Signal Conditioning: Filters out unwanted noise and interference from the signal, improving accuracy and reliability.

How Do Temperature Transmitters Work?

Temperature transmitters are devices used in industrial processes to measure and communicate temperature data. They work by converting the signal from a temperature sensor (such as a thermocouple or RTD) into a standardized output signal, typically a 4-20 mA current loop. Here’s a breakdown of how they work:

Temperature Sensing: The process begins with a temperature sensor, which detects the temperature of the measured environment or substance. Common types of sensors include thermocouples, resistance temperature detectors (RTDs), and thermistors.

Signal Conversion: The sensor produces a weak electrical signal, often in millivolts (mV) for thermocouples or varying resistance for RTDs. The temperature transmitter’s primary function is to convert this signal into a more usable format.

Linearization and Amplification: The transmitter linearizes the signal, meaning it corrects for any non-linear relationships between temperature and the sensor’s output. It then amplifies the signal to a level suitable for transmission over longer distances.

Standardized Output: The linearized and amplified signal is then converted into a standardized output, usually a 4-20 mA current loop. In this system, 4 mA represents the minimum temperature in the range, and 20 mA represents the maximum temperature. Any temperature within the range is represented by a corresponding current value between 4 mA and 20 mA.

Transmission: The 4-20 mA current signal is transmitted through copper wires to a receiving device, such as a controller, PLC, DCS, or monitoring system. This signal can be easily interpreted and used to control processes, display temperature readings, or log data.

Why Are Temperature Transmitters Essential?

“Temperature transmitters” are essential for several reasons across various industries and applications:

Accurate Temperature Monitoring and Control

Temperature transmitters provide precise and reliable temperature measurements, which are crucial for maintaining optimal conditions in many processes. Inaccurate readings can lead to inefficiencies, product defects, and even safety hazards.

Remote Monitoring and Data Transmission

These devices convert temperature readings from sensors into standardized electrical signals (e.g., 4-20mA) that can be transmitted over long distances to control systems or monitoring stations. This allows for centralized monitoring and control of temperature in large or complex systems.

Signal Conditioning and Noise Reduction

Temperature transmitters often include signal conditioning features such as linearization, amplification, and filtering. This improves the accuracy of the temperature signal by compensating for sensor non-linearities and reducing electrical noise.

Increased Safety

In many industrial settings, temperature transmitters are crucial for safety. They can trigger alarms or shut down processes if temperatures exceed safe limits, preventing equipment damage, product spoilage, or even catastrophic events.

Calibration of temperature transmitters is essential to maintain precise temperature monitoring and control. Siemens in Iraq has been actively involved in improving the country’s energy infrastructure. Siemens in Iraq has signed multiple agreements to upgrade power plants and expand the electrical grid.

The presence of Endress+Hauser in Dubai ensures that regional clients have access to cutting-edge technology and professional assistance. Endress Hauser in Dubai also conducts training sessions and workshops to help customers maximize the use of their instrumentation.

Benefits of Smart Transmitters

Smart transmitters offer numerous benefits over traditional analog transmitters in industrial process control and automation. Here are some of the key advantages:

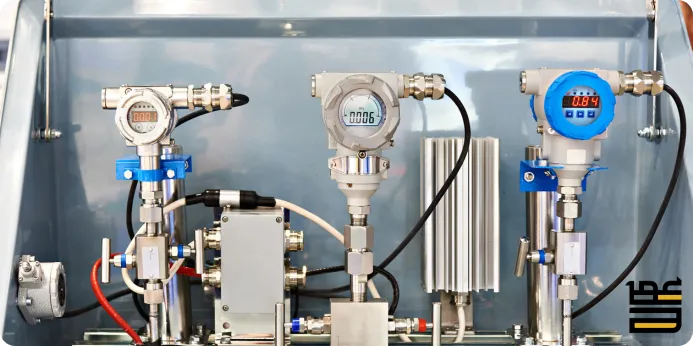

Smart transmitters use digital technology and advanced algorithms for signal processing, resulting in higher measurement accuracy and reduced drift over time. This leads to improved process control and optimization.

Smart transmitters often utilize digital communication protocols like HART, FOUNDATION Fieldbus, or Profibus PA, enabling them to transmit additional information beyond the measured process variable. This includes diagnostic data, device status, and configuration parameters, which can be easily integrated into control systems and asset management software.

Smart transmitters have built-in diagnostics that can detect and report issues such as sensor drift, calibration errors, or process abnormalities. This allows for proactive maintenance, minimizing downtime and optimizing operational efficiency.

The digital communication capabilities of smart transmitters allow for real-time monitoring and remote access to device data. This enables operators and engineers to adjust setpoints, control parameters, and operational strategies on the fly, improving process responsiveness and flexibility.

Conclusion

In conclusion, temperature transmitters are indispensable tools that enhance temperature measurement and control, driving efficiency, safety, and productivity in various industrial and commercial settings. Their continued evolution, incorporating digitalization and smart technologies, promises even greater advancements in temperature monitoring and management.