Which Industries Use Siemens Process Instrumentation?

Introduction

Siemens process instrumentation is integral to a wide range of industries due to its reliability, precision, and advanced technological capabilities. These instruments are essential for monitoring, controlling, and optimizing various industrial processes, ensuring efficiency, safety, and compliance with regulatory standards. These industries leverage Siemens process instrumentation for its advanced features, such as digitalization capabilities, which allow for real-time monitoring, data analysis, and integration with broader industrial automation systems.

Everything about Siemens process instrumentation

Key Components of Siemens Process Instrumentation

Siemens process instrumentation encompasses a wide range of devices and systems designed to measure and control industrial processes. Here are the key components:

Flow Measurement:

- Electromagnetic Flow Meters: Used for conductive liquids.

- Coriolis Flow Meters: For measuring mass flow and density.

- Ultrasonic Flow Meters: Non-invasive measurement for liquids and gases.

- Vortex Flow Meters: Suitable for gases, liquids, and steam.

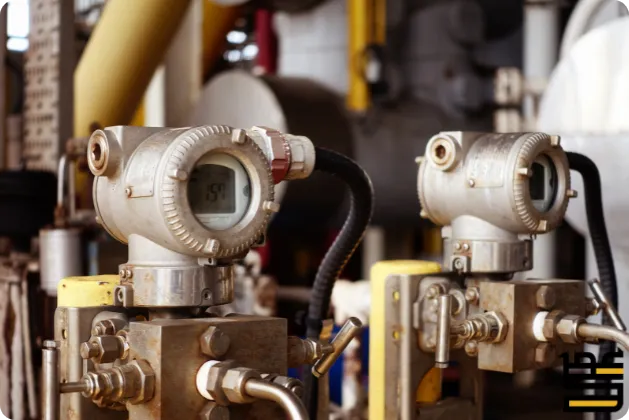

Pressure Measurement:

- Pressure Transmitters: Used for measuring pressure in gases, liquids, and steam.

- Differential Pressure Transmitters: For applications such as level, flow, and filter monitoring.

Level Measurement:

- Radar Level Transmitters: Non-contact measurement for liquids and solids.

- Ultrasonic Level Transmitters: Non-contact measurement for liquids.

- Capacitive Level Sensors: For continuous and point level detection.

- Hydrostatic Level Sensors: Used for measuring liquid levels.

Temperature Measurement:

- RTD (Resistance Temperature Detectors): For precise temperature measurement.

- Thermocouples: Used in a wide range of temperatures and environments.

- Temperature Transmitters: Convert temperature sensor signals to standardized output.

Weighing and Batching Systems:

- Load Cells: Measure weight or force.

- Weighfeeders: For continuous weighing of bulk materials.

- Belt Scales: Measure the flow rate of bulk materials on a conveyor.

Abb in Dubai offers a wide range of solutions and services for the industrial sector, emphasizing sustainability and technological advancement. Abb in Dubai provides cutting-edge automation and electrification products to meet the region’s growing demand for efficient energy solutions. The presence of Abb in Dubai supports local industries by delivering tailored solutions that enhance productivity and reduce environmental impact.

Benefits of Using Siemens Process Instrumentation

Using Siemens process instrumentation offers numerous benefits across various industries, enhancing operational efficiency, accuracy, and reliability. Here are some key advantages:

High Accuracy and Precision

- Reliable Measurements: Siemens instruments provide highly accurate and precise measurements, essential for maintaining quality and consistency in processes.

- Advanced Technology: Utilization of cutting-edge technology ensures minimal errors and high repeatability in readings.

Versatility

- Wide Range of Applications: Siemens offers a broad portfolio of instruments suitable for diverse applications, including temperature, pressure, flow, and level measurements.

- Adaptability: Instruments can be tailored to specific industrial needs, making them versatile across different sectors such as oil & gas, chemical, pharmaceuticals, and food & beverage.

Ease of Integration

- Compatibility: Siemens process instruments are designed to integrate seamlessly with existing systems and control architectures.

- Standard Protocols: Support for standard communication protocols (e.g., HART, PROFIBUS, Modbus) facilitates easy integration and interoperability.

Enhanced Safety and Compliance

- Regulatory Compliance: Instruments are designed to meet stringent industry standards and regulations, ensuring compliance with safety and quality guidelines.

- Fail-Safe Operations: Features such as self-diagnostics and fail-safe modes enhance operational safety and reliability.

Applications of Siemens Process Instrumentation

“Siemens process instrumentation” is used in a variety of industries to ensure the accuracy, reliability, and efficiency of processes. Here are some key applications:

Oil and Gas Industry

- Flow Measurement: Ensures accurate flow rates of crude oil, natural gas, and refined products.

- Level Monitoring: Measures the levels in storage tanks, pipelines, and processing units.

- Pressure Monitoring: Manages pressure in pipelines, refineries, and gas processing plants.

- Temperature Measurement: Controls temperatures in various stages of extraction, refining, and distribution.

Chemical Industry

- Flow Control: Regulates the flow of chemicals in production lines.

- Level Control: Ensures the correct levels in reactors, storage tanks, and silos.

- Temperature Control: Maintains the necessary temperature for chemical reactions.

- Pressure Control: Monitors and controls pressure in reactors and piping systems.

Choosing the Right Siemens Instrumentation for Your Needs

Selecting the right Siemens instrumentation for your needs involves understanding the specific requirements of your application and the capabilities of various Siemens products. Siemens offers a comprehensive range of instrumentation, including flow, level, pressure, temperature, and process protection devices.

Each type of instrument is designed to meet specific industrial challenges and performance criteria. For instance, Siemens flow measurement devices utilize various technologies such as electromagnetic, Coriolis, ultrasonic, and vortex to ensure precise and reliable flow data for different media and process conditions. Identifying the correct technology for your application, whether it involves liquids, gases, or steam, is crucial for achieving accurate measurements and optimizing operational efficiency.

Another critical factor in choosing the right Siemens instrumentation is considering the environmental and operational conditions. Siemens instruments are engineered to withstand harsh industrial environments, including extreme temperatures, high pressures, corrosive substances, and explosive atmospheres. The petrochemical industry is subject to various environmental and safety regulations. Calibrated instruments help companies comply with these regulations by accurately monitoring emissions, waste, and other parameters.

Understanding the specific environmental conditions of your application helps in selecting instruments with appropriate materials and protection ratings, ensuring longevity and reliability. For example, Siemens pressure transmitters are available with different types of diaphragms and housings to resist chemical corrosion, while their temperature sensors can be equipped with protective sheaths for high-temperature applications.

Conclusion

Choosing the Right Siemens Instrumentation for Your Needs” aims to provide comprehensive guidance on selecting appropriate instrumentation solutions from Siemens. By examining factors such as technical specifications, industry-specific requirements, and budget considerations, this guide equips readers with the knowledge to make informed decisions. Whether evaluating process automation tools, analytical instruments, or measurement devices, understanding the capabilities and features of Siemens products ensures optimal performance and efficiency. Ultimately, this resource serves as a valuable tool for professionals seeking reliable instrumentation solutions tailored to their specific operational needs.