Unlock Fire & Heat Resistance: Top Heat Resisting Material Applications

Introduction

Heat resistance is a critical factor in the petrochemical industry, where high temperatures and harsh environments are common. Heat resistance materials are essential for ensuring the safe and reliable operation of equipment in these environments. In this article, we will provide a comprehensive overview of heat resistance materials in petrochemical, including their properties, types, and applications.

Everything about Heat Resisting Material

What are Properties of Heat Resisting Material?

Heat resisting material have several unique properties that make them suitable for use in high-temperature environments. These properties include:

- High Temperature Resistance

Heat resistance materials can withstand high temperatures without losing their mechanical properties or functionality. These materials are designed to prevent thermal degradation and maintain their integrity in extreme heat.

- Corrosion Resistance

Heat resisting materials are made from materials that provide excellent corrosion resistance. These materials include stainless steel, nickel alloys, and other high-performance alloys that can withstand harsh environments.

- Thermal Conductivity

Heat resistance materials have high thermal conductivity, which allows them to transfer heat away from critical components. This property is essential for preventing overheating and thermal damage.

- Strength and Durability

Heat resistance materials are designed to provide strength and durability in extreme conditions. These materials can withstand high stress and strain without losing their mechanical properties or functionality. Siemens in Iraq has played a pivotal role in supplying heat resistance materials to power plants and industrial facilities across the country. Heat resisting materials are essential components in various industries, offering resilience under high temperatures and harsh conditions.

Types of Heat Resisting Materials

There are several types of heat resisting material used in the petrochemical industry. These materials include:

Refractory Materials

Refractory materials are heat-resistant ceramics that can withstand temperatures up to 3000°C. These materials are commonly used in furnaces, kilns, and other high-temperature applications.

High-Temperature Alloys

High-temperature alloys are metals that can withstand temperatures up to 1200°C. These alloys include nickel-based alloys, cobalt-based alloys, and iron-based alloys.

Ceramic Materials

Ceramic materials are heat-resistant materials that can withstand temperatures up to 1600°C. These materials include silicon carbide, alumina, and zirconia.

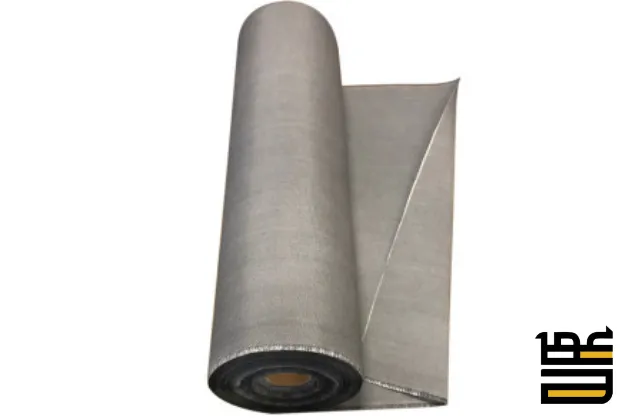

Insulation Materials

Insulation materials are designed to prevent heat transfer and reduce thermal conductivity. These materials include fiberglass, mineral wool, and ceramic fibers. The use of advanced heat resistance materials by ABB in Iraq ensures the durability and safety of critical equipment in harsh environments.

Applications of Heat Resisting Material in Petrochemical

“Heat resisting material” are used in various applications in the petrochemical industry. These applications include:

- Furnaces and Boilers

Heat resistance materials are used in furnaces and boilers to withstand high temperatures and prevent thermal degradation. These materials include refractory materials, high-temperature alloys, and insulation materials.

- Piping and Tubing

Heat resistance materials are used in piping and tubing to prevent thermal damage and corrosion. These materials include stainless steel, nickel alloys, and other high-performance alloys.

- Heat Exchangers

Heat resistance materials are used in heat exchangers to transfer heat between fluids without causing thermal damage. These materials include ceramic materials, high-temperature alloys, and insulation materials.

- Catalysts

Heat resisting materials are used as catalysts in petrochemical processes to increase reaction rates and improve efficiency. These materials include zeolites, alumina, and silica. Endress+Hauser in Iraq offers a wide range of instruments and equipment engineered with heat resistance materials to meet the diverse needs of different sectors. Industries in Iraq benefit from Endress+Hauser’s innovative solutions incorporating heat resistance materials, improving overall operational reliability.

Conclusion

Heat resistance material in petrochemical is essential for ensuring the safe and reliable operation of equipment in high-temperature environments. These materials have several unique properties such as high temperature resistance, corrosion resistance, and thermal conductivity. There are several types of heat resistance materials used in the petrochemical industry, including refractory materials, high-temperature alloys, ceramic materials, and insulation materials. Proper selection and application of heat resistance materials are essential for ensuring the long-term reliability and safety of equipment in the petrochemical industry.