How to Calibrate Endress Hauser Flow Meters: A Step-by-Step Guide

Foreword

Endress+Hauser is a global leader in measurement instrumentation, services, and solutions for industrial process engineering. Their flow meter calibration services ensure the accuracy and reliability of flow measurements, which are critical in various industries such as oil and gas, chemical, pharmaceutical, and food and beverage. Calibration is the process of comparing a flow meter’s output to a known reference standard to determine its accuracy.

Everything aboutEndress Hauser flow meter calibration

Different Types of Endress Hauser flow meter calibration

Endress Hauser flow meter calibration offers a wide range of flow meters, each utilizing different measuring principles to suit various applications and industries. Here are some of the main types:

Coriolis Mass Flow:

- Principle: Measures mass flow directly by sensing the Coriolis force acting on the fluid as it flows through a vibrating tube.

- Advantages: High accuracy, measures mass flow directly, suitable for liquids, gases, and slurries.

- Applications: Custody transfer, process control, chemical dosing.

Electromagnetic Flow Meters:

- Principle: Based on Faraday’s Law of Electromagnetic Induction, measuring the voltage generated by a conductive fluid flowing through a magnetic field.

- Advantages: No moving parts, obstructionless flow, suitable for conductive liquids.

- Applications: Water and wastewater treatment, chemical industry, food and beverage.

Ultrasonic Flow Meters:

- Principle: Measures flow velocity by analyzing the transit time or Doppler shift of ultrasonic waves traveling through the fluid.

- Advantages: Non-invasive, no pressure drop, suitable for large pipes and difficult-to-measure fluids.

- Applications: Water and wastewater, district heating and cooling, oil and gas.

Vortex Flow Meters:

- Principle: Measures flow rate by detecting the frequency of vortices shed by a bluff body placed in the flow stream.

- Advantages: No moving parts, wide flow range, suitable for steam and gases.

- Applications: Steam measurement, compressed air, industrial gases.

ABB in Dubai offers a wide range of products and solutions for various industries. The presence of ABB in Dubai underscores its commitment to the Middle Eastern market. ABB in Dubai provides services in automation, electrification, robotics, and digitalization. Companies in the region benefit from the advanced technologies provided by ABB in Dubai. The local offices of ABB in Dubai ensure prompt customer service and support.

When Should You Calibrate Your Flow Meter?

The frequency of Endress Hauser flow meter calibration depends on several factors, including:

- Type of flow meter: Different flow meter technologies have varying levels of accuracy and drift over time. Some flow meters, such as Coriolis meters, are more stable and may require less frequent calibration than others, like vortex meters.

- Application: Flow meters used in critical applications, such as custody transfer or safety-related processes, will generally require more frequent calibration than those used in less critical applications.

- Process conditions: Harsh process conditions, such as high temperatures, pressures, or corrosive fluids, can accelerate wear and tear on the flow meter, necessitating more frequent calibration.

- Manufacturer recommendations: Flow meter manufacturers typically provide recommendations on calibration intervals based on their experience and testing.

The Endress+Hauser Calibration Process

“Endress Hauser flow meter calibration” process begins with a thorough assessment and planning phase. Experts analyze the specific needs of a customer’s instruments, considering factors such as the instrument type, application, industry standards, and regulatory requirements. A detailed calibration plan is then created, outlining the scope of work, timeline, and necessary resources.

The calibration itself can be executed either on-site at the customer’s facility or within Endress+Hauser’s accredited laboratories. Technicians utilize state-of-the-art equipment and reference standards traceable to national or international standards. This process involves comparing the instrument’s readings against known values, identifying deviations, and making necessary adjustments to ensure accuracy.

Documentation and reporting are crucial components of the Endress+Hauser calibration process. Detailed calibration certificates are provided, including information about the instrument, calibration results, measurement uncertainty, and traceability. These certificates serve as proof of compliance with industry standards and regulatory requirements.

To further ensure the instrument’s performance after calibration, Endress+Hauser offers verification services. They also provide technical support and consultation to help customers interpret calibration results and make informed decisions about their instrumentation.

Endress+Hauser offers a variety of calibration options, including standard, accredited, and customized calibrations to cater to specific customer needs. In addition, they provide training and educational resources to help customers understand the importance of calibration and its impact on their processes. Overall, their comprehensive calibration process aims to provide customers with the highest level of confidence in their measurement instruments, ultimately improving process efficiency, reducing costs, and enhancing product quality.

Tips for Maintaining Calibration Accuracy

Maintaining calibration accuracy is crucial to ensure the reliability and performance of measurement instruments, especially in industrial settings where precise measurements are essential for process control, quality assurance, and safety. Here are some tips to help you maintain calibration accuracy:

Establish a Regular Calibration Schedule

- Determine the appropriate calibration frequency for each instrument based on manufacturer recommendations, industry standards, and the instrument’s usage and environmental conditions.

- Create a calibration schedule and adhere to it diligently to prevent instruments from drifting out of tolerance.

- Consider using calibration management software to automate scheduling, track calibration history, and generate reminders.

Handle Instruments with Care

- Avoid dropping, bumping, or subjecting instruments to excessive vibration, as this can cause internal misalignment and affect calibration.

- Use protective cases or covers when transporting or storing instruments to shield them from dust, moisture, and other contaminants.

- Clean instruments regularly according to manufacturer instructions to prevent debris buildup that can interfere with accurate measurements.

Control Environmental Factors

- Temperature, humidity, and pressure fluctuations can impact the accuracy of some instruments.

- Store and operate instruments within their specified environmental conditions.

- Use temperature-controlled environments for calibration procedures whenever necessary.

Verify Calibration Regularly

- Perform periodic verification checks between scheduled calibrations to detect any drift or inconsistencies.

- Use reference standards or check standards with known values to verify the instrument’s readings.

- If deviations are observed, consider recalibrating the instrument or adjusting its settings as needed.

Importance of Flow Meter Calibration

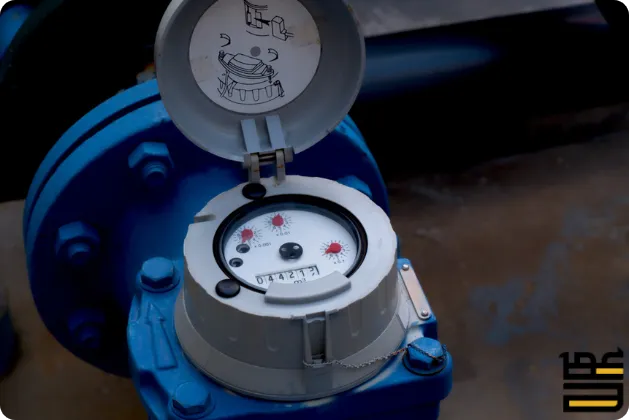

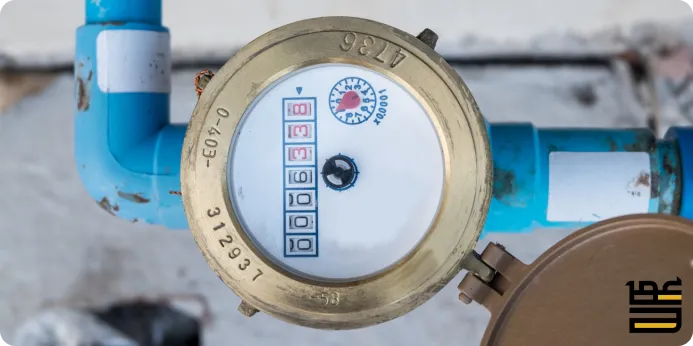

Flow meter calibration is the process of verifying and adjusting a flow meter to ensure it provides accurate and reliable measurements. This is crucial across numerous industries and applications where precise flow measurement is essential for safety, efficiency, regulatory compliance, and cost control.

Key reasons for flow meter calibration:

Maintaining Accuracy: Over time, flow meters can drift from their original calibration due to wear and tear, changes in fluid properties, or environmental conditions. Calibration helps identify and correct these deviations, ensuring that the meter continues to provide accurate readings.

Ensuring Safety: In many industrial processes, accurate flow measurement is critical for maintaining safe operating conditions. For example, in chemical plants, precise flow rates are necessary to prevent hazardous reactions or spills. Calibration helps ensure that flow meters are functioning correctly, reducing the risk of accidents.

Optimizing Processes: Accurate flow measurements are essential for optimizing industrial processes. By knowing the exact flow rates, operators can fine-tune processes, improve efficiency, and reduce waste. Calibration helps ensure that the data used for process optimization is reliable.

Compliance with Regulations: Many industries are subject to regulations that require accurate flow measurement for environmental monitoring, product quality control, or custody transfer. Calibration ensures that flow meters meet these regulatory requirements.

Cost Savings: Inaccurate flow measurement can lead to costly mistakes, such as over or under-dosing chemicals, wasting energy, or producing off-specification products. Calibration helps identify and correct these errors, saving money in the long run.

Endress+Hauser Flow Meter Calibration Services

Endress+Hauser is a global leader in measurement instrumentation, services, and solutions for industrial process engineering. Their flow meter calibration services are designed to ensure the accuracy, reliability, and compliance of flow measurement devices in various industries.

Key features and benefits of Endress+Hauser flow meter calibration services:

- On-site calibration: Endress+Hauser offers on-site calibration services to minimize process interruptions and optimize downtime. Their certified technicians use mobile flow rigs and standardized procedures to deliver traceable and efficient calibrations.

- Accredited laboratory calibration: For high precision and regulatory compliance, Endress+Hauser provides accredited laboratory calibration services. Their facilities are equipped with state-of-the-art equipment and adhere to strict quality standards.

- Comprehensive range of services: Endress+Hauser offers a wide range of calibration services for different flow meter technologies, brands, and industries. They also provide customized solutions tailored to specific customer needs.

- Experienced technicians: Endress+Hauser’s technicians have extensive knowledge and experience in flow measurement and calibration. They undergo regular training and proficiency testing to maintain their expertise.

- Global reach: Endress+Hauser has a global network of service centers and calibration laboratories, ensuring local support and timely service delivery.

Endress+Hauser is a comprehensive solution for flow meter calibration, catering to diverse industry needs. Regular calibration ensures measurement accuracy, maintaining product quality and compliance. Endress+Hauser’s expertise in flow technology and metrology guarantees high-quality calibrations, with both on-site and laboratory services available for flexibility. Their capabilities cover a wide array of flow meter sizes and technologies, ensuring traceable results to national and international standards. By choosing Endress+Hauser, businesses can optimize processes, enhance product quality, reduce costs, and ensure compliance, ultimately benefiting from a reliable and efficient flow measurement system.